Machine catalog & sourcing notes

These are the most requested machine families across forging and die casting programs. Each request is tailored to alloy, part geometry, locking force/tonnage, automation, and utilities.

3 items

High-force presses used for controlled deformation and repeatable forging cycles—well-suited for large parts and precision work.

Highlights

- High tonnage options

- Programmable stroke/pressure

- Consistent part quality

Typical use cases

Impact-based forging equipment for shaping hot metal quickly—commonly used for open-die and certain die-forging operations.

Highlights

- High-impact forming

- Simple setup

- Good for varied jobs

Typical use cases

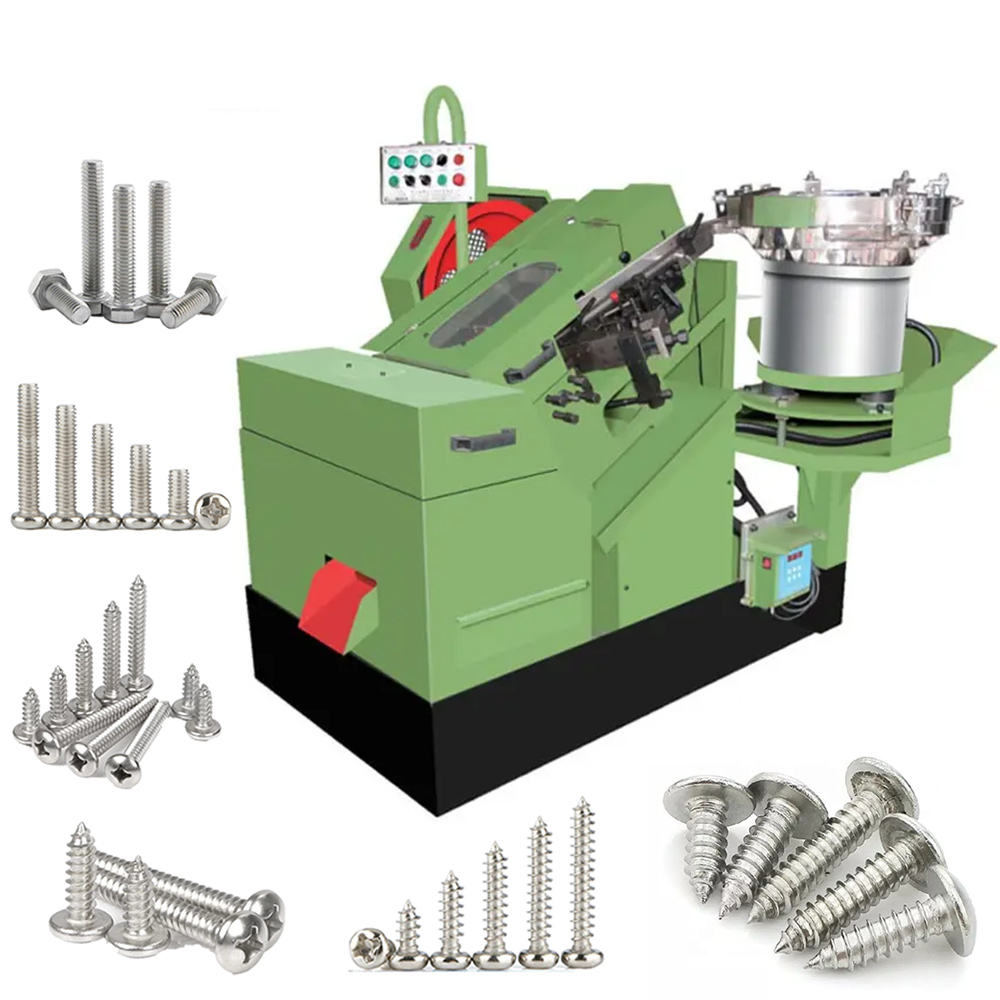

Dedicated equipment to form heads and upset sections of bars/rods with high repeatability for production parts.

Highlights

- Excellent repeatability

- High output

- Designed for bar/rod feed

Typical use cases

2 items

High-pressure die casting machines typically used where the molten metal is ladled into a shot sleeve before injection.

Highlights

- Wide locking-force range

- Automation ready

- Process monitoring options

Typical use cases

Die casting machines designed for rapid cycles where the injection mechanism is immersed—often used for lower melting-point alloys.

Highlights

- Short cycle times

- High repeatability

- Compact footprint options

Typical use cases

1 items

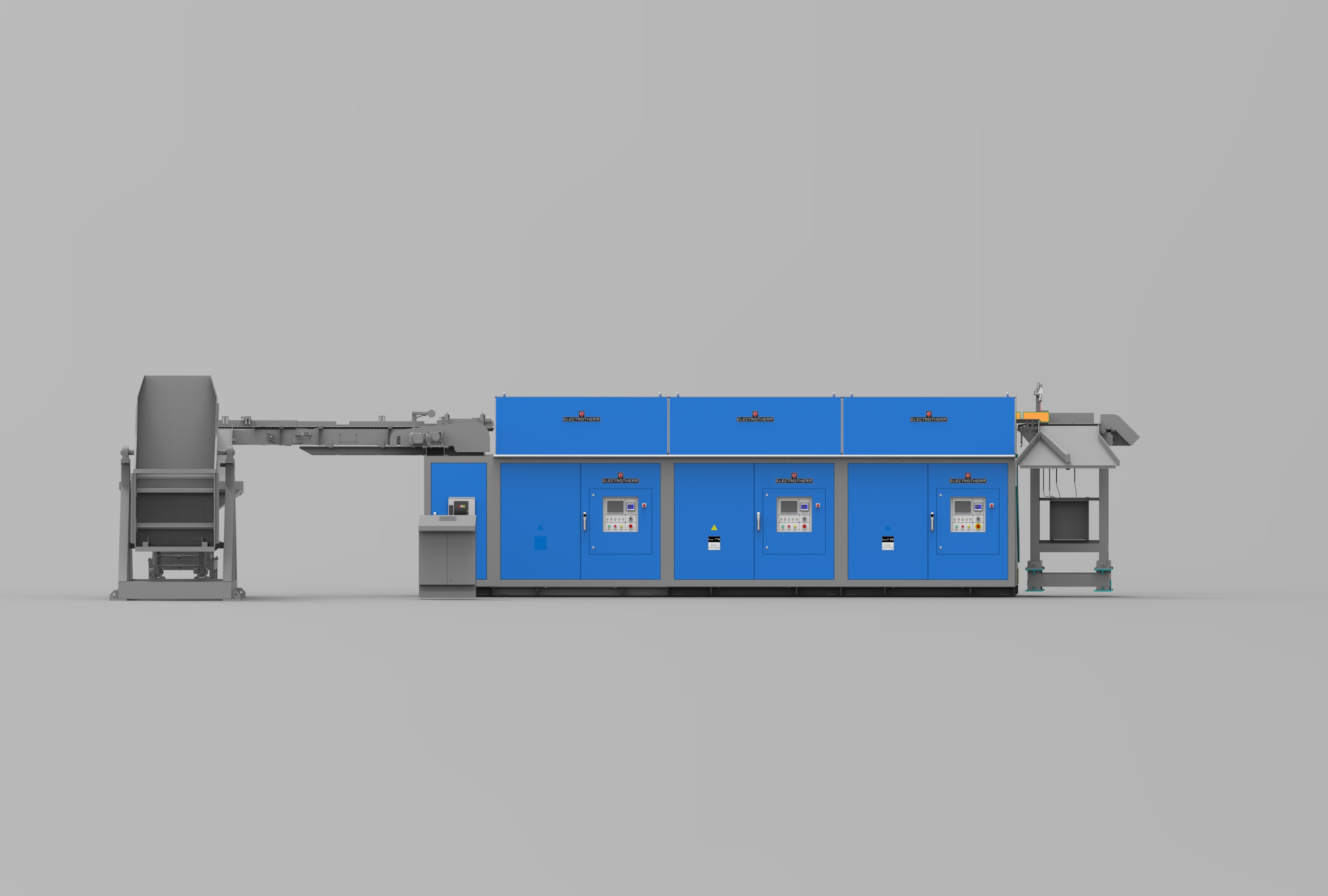

Fast, controllable heating for billets/bars to support stable forging temperatures and throughput.

Highlights

- Rapid heating

- Temperature control

- Efficient energy use

Typical use cases

1 items

Critical spares and consumables for maintaining injection performance and reducing unplanned downtime.

Highlights

- Common sizes supported

- Wear-part focus

- Compatibility guidance

Typical use cases